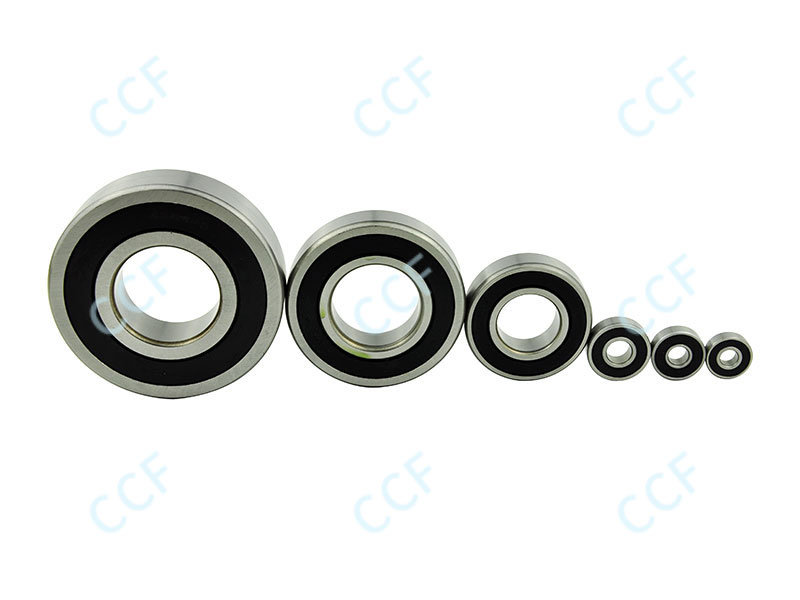

Serious Bearings are mechanical components designed to facilitate the motion of various machine parts by reducing friction between them. They play a crucial role in a wide range of applications, from simple household appliances to complex industrial machinery. The primary functions of bearings include:

Reducing Friction: Bearings are primarily used to reduce friction between two moving or rotating parts. This reduction in friction allows for smoother and more efficient motion, which helps increase the lifespan of the components involved and reduces energy consumption.

Supporting Loads: Bearings provide support for loads, whether they are radial loads (perpendicular to the axis of rotation) or axial loads (parallel to the axis of rotation). They help distribute the weight or force applied to the rotating or moving part evenly, preventing deformation or damage.

Enabling Rotation: Bearings allow parts to rotate around a fixed axis, such as a shaft or axle. They enable the controlled and smooth rotation of components like wheels, gears, pulleys, and more.

Guiding Motion: Bearings can guide the motion of machine parts along a linear path, allowing for precise and controlled linear movement. This is often seen in linear motion systems and conveyor belts.

Reducing Wear and Tear: By reducing friction, bearings help minimize wear and tear on the surfaces of the moving parts. This extends the operational life of machinery and reduces maintenance requirements.

Maintaining Accuracy: Bearings are essential in applications where precision and accuracy are critical, such as in machine tools and robotics. They ensure that moving parts maintain their intended positions with minimal deviation.

Absorbing Shock and Vibration: Bearings can also help absorb and dampen shock and vibrations, improving the stability and performance of machines and vehicles.

Allowing for Easy Replacement:

Serious Bearings are typically replaceable components, making it easier and more cost-effective to maintain machinery. When a bearing wears out or fails, it can be replaced without replacing the entire machine part.

Supporting High-Speed Rotation: Some specialized bearings, like ball bearings and roller bearings, are designed to handle high-speed rotation while maintaining low friction and high load-carrying capacity.

Sealing and Lubrication: Bearings can be equipped with seals to prevent contaminants from entering and to retain lubricants. Proper lubrication is crucial for reducing friction and preventing premature wear.

AUTOMOBILE FAN, SILICON OIL CLUTCH, BEARING

AUTOMOBILE FAN, SILICON OIL CLUTCH, BEARING

Structurally, it takes into account more unexpected situations, thereby improving the efficiency of the fan clutch and effectively extending its lifespan.

In terms of performance, automotive silicone fan clutches can withstand greater loads and will not leak oil due to pressure.