Background and significance of low noise and low friction design

With the improvement of industrial automation level, the requirements of industrial motors for reliability, stability and operating environment in operation are gradually increasing. Especially in places that are sensitive to noise, such as precision equipment, medical machinery, electronic manufacturing and office automation equipment, the vibration and noise level in motor operation has become an important evaluation criterion. Therefore, in the design process of industrial motor ball bearings, more and more attention is paid to the realization of low noise and low friction characteristics to meet the basic needs of users for silent operation and energy efficiency.

Low noise design can reduce structural resonance and vibration transmission during mechanical operation and improve the comfort of the overall equipment. Low friction structure helps to reduce energy loss, control temperature rise, and extend the service life of equipment, which is an important part of improving system efficiency.

Key factors affecting noise and friction in ball bearing structure

In ball bearings, noise and friction mainly come from the contact between rolling elements and raceways, shear resistance of lubricants, friction of cages, and bearing assembly accuracy. Common influencing factors include:

Surface finish of raceways and balls: The smoother the surface, the smaller the vibration and friction during operation.

Cage design and material: Suitable cage materials (such as nylon or resin) and stable clearance control help absorb vibration and reduce friction.

Internal clearance setting: Reasonable internal clearance can reduce running interference and improve stability.

Type of grease or oil: Low viscosity, low noise special lubricants can effectively control the friction coefficient and running noise.

Typical structural characteristics of low noise bearings

Industrial motor ball bearings designed for low noise usually have the following structural characteristics:

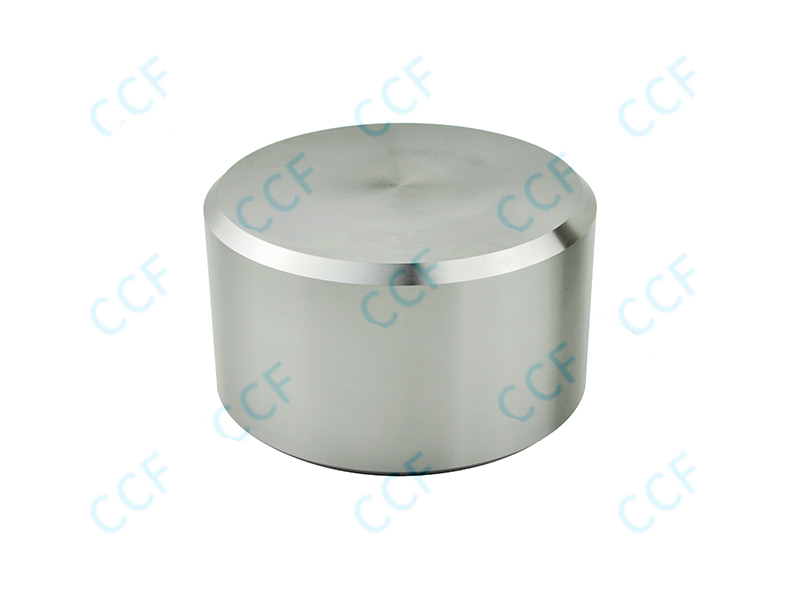

High-precision machining: The roundness error and surface roughness of the raceway and ball are controlled within a low range, which helps to reduce micro-vibration and uneven contact.

Silent cage: The low-noise cage made of engineering plastics has a certain flexibility, which can reduce the metal impact sound during operation.

Optimized contact angle design: The appropriate contact angle can not only ensure the load-bearing capacity, but also avoid axial vibration transmission.

Closed structure: Use rubber sealing rings or metal dust covers to prevent foreign matter from entering, and at the same time play a certain role in sound absorption and buffering.

Performance of low friction design in industrial motors

Industrial motor ball bearings with low friction design usually emphasize maintaining stable speed and temperature rise control when running at high speed or for a long time. This type of bearing mainly adopts the following design strategies:

Use low friction grease: For example, grease with polyalphaolefin base oil and a small amount of additives can maintain thin film lubrication and reduce metal contact.

Reducing seal contact resistance: Some seals are designed as non-contact or light contact to reduce rotation resistance.

Optimizing the raceway angle: Under the premise of ensuring load-bearing capacity, the design of the raceway curvature radius is more gentle, which helps to reduce rolling resistance.

After these designs are applied to bearings, it is beneficial for motors to reduce power consumption, improve efficiency, and delay the wear process during the life cycle of bearings.

Comparison of noise and friction requirements for different applications

The following is a comparative analysis of the low noise and low friction requirements for ball bearings in different industrial motor application fields:

| Application Scenario | Noise Level Requirement | Friction Requirement | Typical Design Features |

|---|---|---|---|

| Medical Equipment | High | Medium | Silent cage, non-contact seal, precision raceway |

| HVAC Blowers | Medium | High | Light-contact seal, low-viscosity grease, optimized contact angle |

| Office Printers | High | Medium | Plastic cage, small clearance, low-noise grade grease |

| Industrial Conveyors | Low | High | Open-type bearing with low-friction grease, metal dust cover |

| Servo Drives | High | High | Angular contact bearing, optimized internal geometry, advanced grease |

Actual impact in installation and maintenance

Even if the bearing itself has a low noise and low friction structural design, the installation and maintenance methods will have a direct impact on its performance. For example:

Coaxiality deviation during assembly can cause eccentric load, leading to unstable operation and increased noise;

Grease contamination or drying can increase friction and accelerate wear;

Inappropriate bearing preload may cause excessive resistance or vibration.

The performance of low-noise and low-friction bearings depends not only on manufacturing design, but also on users to maintain standardized operations during installation, lubrication, and use cycles.

Development trend of low-noise and low-friction technology

At present, the development trend of industrial motor ball bearings is gradually moving towards intelligence, modularization and high reliability. Regarding low-noise and low-friction design, it is mainly reflected in the following aspects:

Nano-coating technology: reducing friction coefficient through surface coating;

Increased application of ceramic balls: some motors use hybrid ceramic bearings to improve speed stability and reduce friction;

Intelligent monitoring module: equipped with temperature and vibration sensors to grasp the operating status in real time;

Development of green lubricants: higher performance, more environmentally friendly low-viscosity lubricating materials are gradually being used.

The promotion of these technologies will further improve the quietness and efficiency of motor operation and meet the actual needs of more industries for low-noise environment and efficient operation.