Motorcycle bearings play a critical role in the smooth rotation of wheels, crankshafts, and other moving components. Improper installation can disrupt alignment, increase friction, and reduce the lifespan of the bearing itself as well as surrounding mechanical components. Correct installation ensures that bearings function under the intended load distribution and rotational speeds. When installation is neglected or conducted without proper tools, the result can be increased wear, heat generation, and potential mechanical failures. Motorcycle performance, safety, and reliability depend heavily on the correct seating and alignment of bearings, making installation procedures a fundamental aspect of maintenance and assembly.

Several errors can occur during the installation of motorcycle bearings. These include using excessive force, misalignment during press fitting, insufficient lubrication, and contamination of the bearing surfaces. Applying direct hammer blows or unbalanced pressure may deform the bearing raceways or balls, creating uneven load distribution. Misalignment between the bearing and shaft or housing leads to uneven stress concentrations, accelerating wear and potentially causing early failure. Lack of lubrication increases friction and heat, reducing the bearing's ability to support rotational motion efficiently. Contaminants such as dirt or metal particles introduced during installation can scratch surfaces, further reducing operational reliability. Each of these errors contributes to mechanical vulnerabilities that may manifest as failures over time.

Applying excessive force when pressing a bearing into place can create internal damage. The rolling elements may become dented or skewed, resulting in uneven rotation. Deformation of the outer or inner race alters load distribution, increasing stress on specific points. Over time, these deformations may develop into cracks, spalling, or material fatigue. Excessive force may also stress the surrounding components, including shafts and housings, leading to dimensional inconsistencies and alignment issues. Even minor internal damage can amplify vibrations, reduce efficiency, and accelerate the wear of other drivetrain components.

Misalignment occurs when the bearing is not correctly seated relative to the shaft or housing. This can be angular misalignment, axial offset, or radial displacement. Misaligned bearings experience uneven load distribution across the rolling elements, which results in higher localized stress and accelerated wear. The increased friction generates heat, potentially altering lubricant properties and reducing the bearing’s ability to operate under load. Misalignment may also induce vibrations and noise, which can propagate to connected components, affecting overall motorcycle stability and control. Long-term misalignment can lead to complete bearing failure, which may affect wheel rotation, engine efficiency, or transmission performance.

Lubrication is crucial to bearing performance, reducing friction between rolling elements and raceways. During installation, failure to apply appropriate grease or oil can increase initial wear. Insufficient lubrication may cause metal-to-metal contact, creating heat and accelerating the degradation of the bearing. This not only reduces bearing life but also impacts surrounding components such as shafts, gears, or wheel hubs. Over time, heat buildup may also change the properties of nearby seals or synthetic materials, creating additional points of failure. Correct lubrication ensures smooth start-up performance and prevents early-stage damage caused by direct contact between bearing surfaces.

Contaminants introduced during installation, including dust, metal particles, or other debris, compromise bearing integrity. Particles trapped between rolling elements and raceways create scratches, pits, and wear tracks. These imperfections amplify stress concentrations, which may lead to premature fatigue and potential spalling. Contamination can also alter lubricant performance, causing uneven distribution and local hotspots within the bearing. Bearings exposed to contaminants during installation are more prone to vibration, noise, and rapid deterioration. Careful cleaning of components and controlled installation environments help minimize contamination risks and support bearing longevity.

| Failure Type | Cause | Effect on Motorcycle |

|---|---|---|

| Spalling | Excessive force or misalignment | Surface flaking reduces bearing life and increases vibration |

| Premature Wear | Insufficient lubrication | Higher friction and heat, reducing rotational efficiency |

| Cracks in Bearing Races | Excessive load during press fitting | Potential sudden failure, affecting wheel or engine performance |

| Noise and Vibration | Contamination or misalignment | Operational instability and discomfort during riding |

| Seizure | Lack of lubrication or debris | Complete stoppage of rotation, risk of mechanical damage |

Improperly installed bearings can create cascading failures in connected drivetrain components. Excessive heat or vibrations transmitted through the bearing may accelerate wear of gears, shafts, and chains. Axial misalignment can place additional stress on seals and bushings, increasing maintenance requirements and reducing overall system efficiency. Bearings in wheels or swingarms that fail can affect handling and stability, creating safety concerns for riders. Regular inspection after installation is essential to identify early signs of stress or wear in both bearings and surrounding parts.

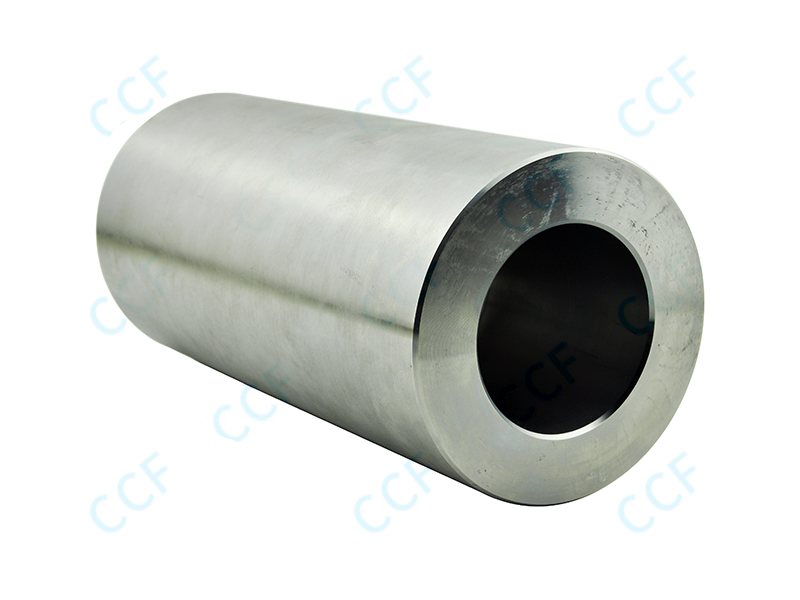

Using proper installation tools such as bearing presses, mandrels, and alignment fixtures is crucial for maintaining bearing integrity. Techniques that ensure even force distribution across the bearing reduce the likelihood of deformation and misalignment. Procedural adherence includes cleaning mating surfaces, pre-lubrication, and temperature control when necessary. By following standardized installation practices, mechanics can minimize mechanical failures and extend bearing service life. Documentation of installation procedures also helps in identifying potential root causes in case of subsequent bearing or component issues.

Even when bearings are installed correctly, routine monitoring is necessary to detect early signs of failure. Periodic checks may include visual inspection, noise detection, vibration analysis, and rotational smoothness assessment. Early detection of irregularities allows replacement or lubrication interventions before complete mechanical failure occurs. Preventive maintenance minimizes downtime, reduces repair costs, and ensures safe motorcycle operation. Combining careful installation with ongoing monitoring supports reliable performance and reduces the risk of cascading mechanical issues caused by bearing failure.

High-performance motorcycles subject bearings to greater speeds, loads, and vibrations. In these scenarios, installation errors are more likely to produce immediate and severe consequences. Misalignment or uneven pressure can quickly translate to bearing overheating, seizure, or shaft damage. Bearings in engines, transmissions, or suspension components require precision installation to withstand dynamic forces. Failure to meet installation specifications in high-performance motorcycles may result in rapid degradation, negatively affecting acceleration, handling, and safety.

Environmental conditions such as dust, moisture, and temperature fluctuations influence how bearing installation quality impacts performance. Bearings installed in humid or dusty environments are more sensitive to contamination, requiring additional care during assembly. Similarly, motorcycles used for off-road riding or in extreme temperatures place additional demands on bearings. Proper installation combined with appropriate protective measures such as seals and lubricants helps mitigate environmental impacts. This ensures that bearings maintain functional integrity despite operational challenges.

Preventing mechanical failures from improper motorcycle bearing installation requires a combination of precise technique, proper tooling, lubrication, and controlled environments. Attention to alignment, force application, cleanliness, and lubrication during installation supports long-term reliability. Periodic inspection, monitoring for vibration or noise, and consideration of operational conditions further reduce the risk of failure. Understanding the interrelationship between bearing installation and overall motorcycle performance is critical for engineers, mechanics, and maintenance personnel aiming to maintain safety, stability, and durability in motorcycle systems.